New innovation in thin-walled cannula unveiled by Accumold at MD&M East event

In the realm of medical device manufacturing, precision and innovation are key. At the upcoming MD&M East 2025 in New York City, from 20-22 May, attendees will have the opportunity to witness first-hand the groundbreaking advancements in micro moulding by Accumold, a company with over 40 years of experience in producing complex micro components with tolerances down to a few microns [1][3][5].

Accumold's expertise lies in the production of extremely small, complex, and precise components that are essential for the creation of smaller, smarter medical devices. Their innovations in micro moulding have been showcased at events such as MD&M East 2025, demonstrating their specialization in tiny, intricate parts tailored particularly for the medical, microelectronics, and optics industries [1].

The focus of Accumold's latest innovations is on producing parts with micro-level precision, a critical factor in cutting-edge medical device technology. The ability to manufacture parts with such precision supports the trend toward miniaturization and increased functionality ("smart" features) in medical devices. This includes enhanced automation compatibility and streamlined assembly processes facilitated by materials and processes designed for longevity and ease of use, such as Accumold's micro-molding solutions and related dispensing materials ideal for automated assembly lines [1].

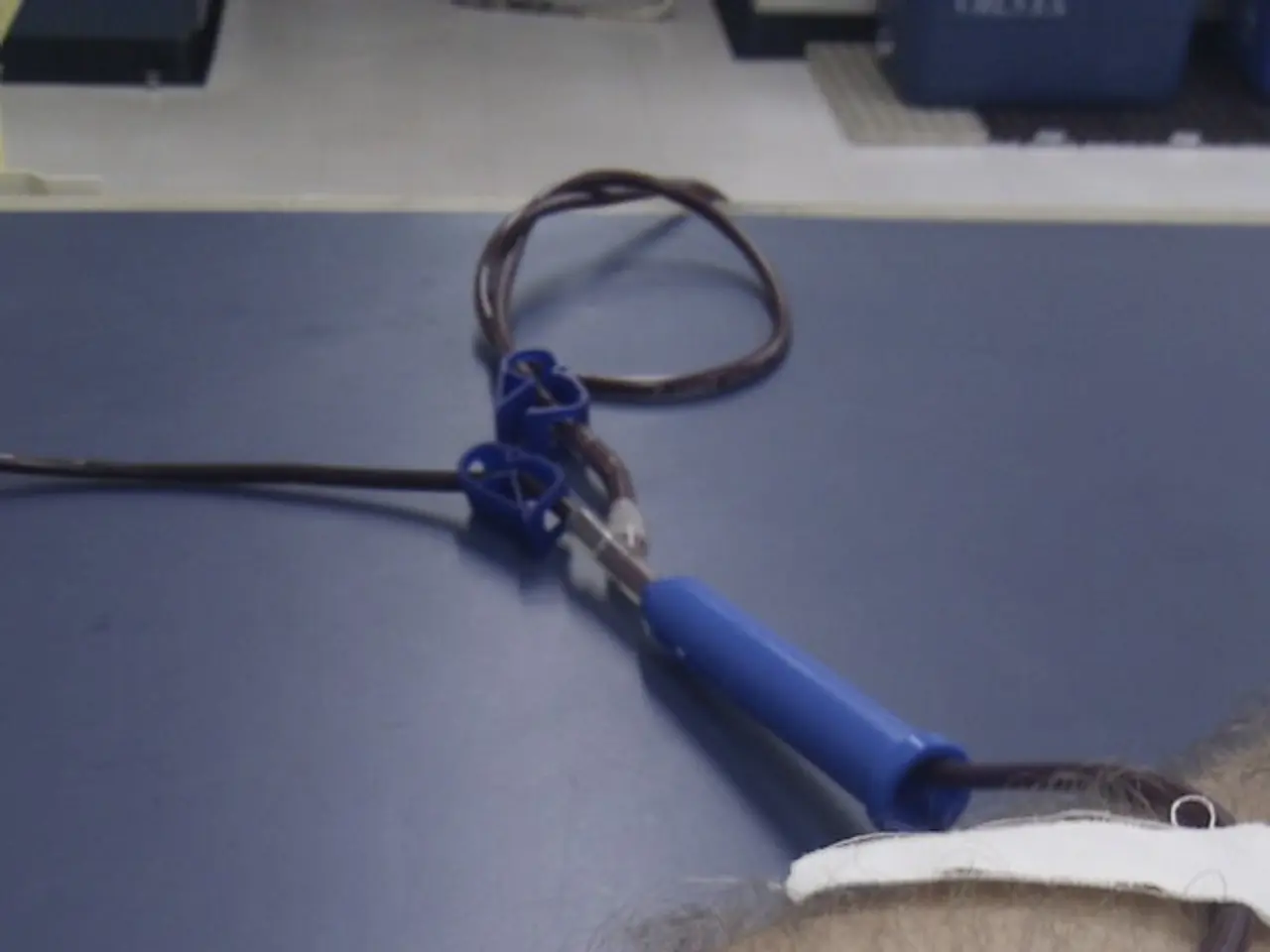

One of the standout advancements from Accumold is their new thin-walled cannula production technique. This technique allows for wall thicknesses as low as 0.1 mm and supports volumes of up to 40 million parts per year per cell. This method has improved part quality and production efficiency, reducing variability and opening up new design possibilities [2].

Brett Saddoris, Technical Sales Manager at Accumold, emphasizes the importance of speed, consistency, and reliability in healthcare manufacturing. He states that this is a major step forward for minimally invasive devices [4]. Visitors at Booth 551 can meet the technical team and discuss how micro moulding for medical devices can accelerate development and reduce time to market.

Accumold works with a variety of materials suitable for surgical tools, diagnostic kits, drug delivery systems, and more, including PEEK, LCP, Polycarbonate, Polypropylene, and Pebax [6]. The company's innovations are not limited to thin-walled cannulas; their expertise extends to micro moulding for medical-grade materials across the board.

For those interested in learning more about the role of micro moulding in wearable diabetes devices, the article "The role of micromoulding in wearable diabetes devices" is available in "Medical Plastics Insights" [7]. Another insightful read is "A lesson in injection moulding of thin wall cannulas", also available in "Medical Plastics Insights" [8].

Accumold's presence at MD&M East 2025 is a testament to their commitment to pushing the boundaries of what is possible in micro moulding for medical devices. Attendees can view micro moulded samples at Booth 551 and witness the future of medical device manufacturing unfold.

- The healthcare manufacturing industry relies heavily on the precision and innovation of companies like Accumold, pioneers in micro moulding and producers of complex medical plastics essential for the creation of smaller, smarter medical devices.

- The medical-conditions sector can benefit from advancements in healthcare manufacturing, such as Accumold's new thin-walled cannula production technique, which promises improved part quality, increased production efficiency, and reduced variability, critical for minimally invasive devices.

- In the health-and-wellness industry, the ability to manufacture parts with micro-level precision, as demonstrated by Accumold, supports the trend toward miniaturization and increased functionality in medical devices, making way for enhanced automation compatibility and streamlined assembly processes.

- The finance and technology sectors play a crucial role in the progress of the medical devices industry, as investments and technological advancements facilitate the accelerated development and reduced time to market of medical devices, a goal that companies like Accumold are actively pursuing.